Waterstop is a crucial construction element used in every building made of concrete. Some of us may not be familiar with its actual working principle. What does it actually do? As the name suggests, its purpose is to stop water. So, we can guess that this material is used to prevent water from entering a space. Yes, these water stoppers prevent the passage of water through joints or gaps in concrete structures. There are various types of water stoppers, where rubber & plastics are most popular. “Rubber waterstop vs PVC waterstop” highlights the fundamental differences between these materials.

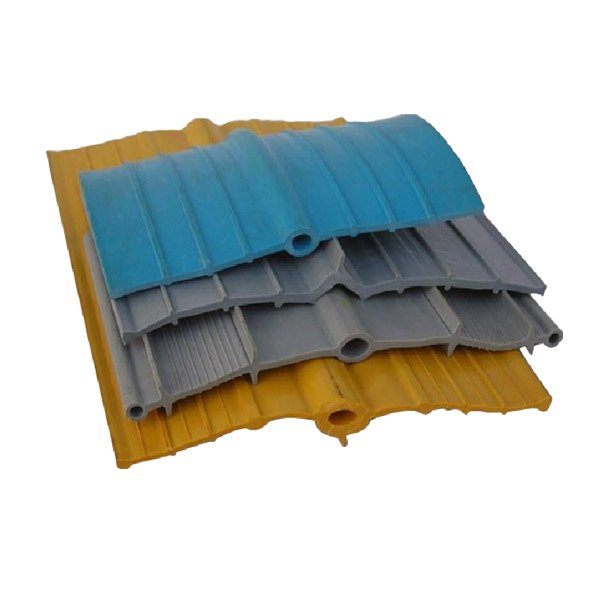

Both rubber waterstop & PVC waterstop are popular in construction applications. They come with a similar structure. Both are divided into the back-mounted type & the middle-buried type. Well, what sets them apart is their distinct materials.

Understanding the differences between these two waterstoppers can help you make informed decisions. It helps you, especially when choosing the right materials for your construction project. We will begin with the difference table so that you can quickly identify the fundamental differences. In the subsequent sections, we will learn more about their types, advantages, and limitations. Moreover, we will talk about some crucial factors you need in the selection process.

Rubber Waterstop vs PVC Waterstop

As mentioned earlier, rubber waterstop & PVC waterstop come with similar structures. What sets them apart is their construction material. Therefore, the following table mainly focuses on the primary material characteristics. When you compare the properties, you will find the suitability of the waterstop in your project.

Table 1 Difference Table Of Rubber Waterstop Vs PVC Waterstop

| Features | Rubber Waterstop | PVC Waterstop |

| Material Composition | Typically made from natural or synthetic rubber compounds, key advantages are flexibility & durability | Composed of polyvinyl chloride; key advantages are chemical resistance & ease of fabrication |

| Types | Internal (CB & CP type) & external (EB & EP) types cover diverse project requirements. | Dumbell, Dumbell with center bulb, ribbed flat, ribbed with center bulb & tear web, base seal, split water-stop, cap water-stop |

| Flexibility | Excellent elongation, accommodating structural movements | Less flexible than rubber waterstop |

| Corrosion resistant | Generally resistant to corrosion but not as good as PVC water stop | Excellent corrosion resistant |

| Tensile strength | Exhibit good tensile strength | Known for high tensile strength |

| Temperature resistance | Suitable for a wide range of temperature applications | Excellent for low-temperature applications |

| Durability | Durable; withstands various environmental conditions | Also durable & long-lasting |

| Advantages | Excellent flexibility, adaptability to irregular shapes | High chemical resistance, low-temperature resistance, and Versatile |

| Limitations | Susceptible to edging, may require more maintenance | Limited flexibility in comparison to rubber may not be suitable for irregular surfaces |

| Cost | Competitively priced | Generally cheaper than rubber waterstop |

Rubber Waterstop

A rubber waterstop is a popular type used as a construction material. You know, its primary function is to prevent the passage of water through joints in concrete structures. Rubber water stops are used more often than PVC water stops in this case. Popular manufacturing processes include plasticization, mixing, extrusion, compression molding, and vulcanization. There are different types of Rubber waterstop. We have categorized them into two main sections.

- Based on usage

- Buried waterstop is a mostly used rubber waterproofing material. They are commonly seen in the construction of underground concrete structures.

- The back stick-type waterstop is made of a combination of natural rubber & synthetic rubber. Their composition also includes many additives & fillers. It mainly comes from plasticization, mixing, and compression molding.

- Based on the form

- CB-type water stop: They are the middle hole of the buried water stop.

- CP-type water stop: They are in the middle of nonporous buried water.

- EP-type water stops: They are also known as externally bonded waterstops or backing water stops. It indicates that water stops are marked outside the center of the no-pass.

- EB-type water stop: They are also known as posted outside water stop or backing with water stop.

Advantages

- Rubber water stop provides excellent flexibility.

- They provide excellent water-tightness.

- They exhibit good chemical resistance.

- Durable & efficient

- Rubber water stops can accommodate irregular surfaces.

Limitations

- Rubber water stops may be good for flexibility, but they are not ideal for low-temperature applications.

- Unlike PVC water stops, they can’t promise excellent corrosion resistance

PVC Waterstop

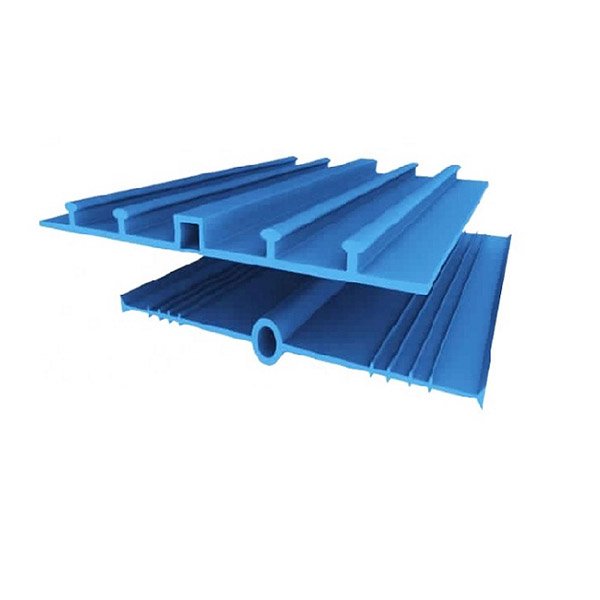

These are another type of waterstops mainly used as joint fillers in concrete structures. PVC water stoppers are used primarily to accommodate movements & settlements in concrete structures. Although they are also used to prevent the passage of water. PVC water stops also come in various types.

- Dumbell waterstop is the largest & thickest profile. They are ideal for construction joints & contraction joints.

- Dumbell with a center bulb can withstand large-scale movements. They are also the largest & thickest waterstop profiles.

- Ribbed flats are designed to enhance the bond strength between waterstop & surrounding concrete.

- Ribbed with center bulbs are designed to absorb the shear movements. It can be lateral or transversal direction.

- Ribbed with a tear web, it has a U-shaped center bulb. Its primary function is to tear when being subjected to large movements. Typical situations include joint expansion or differential settlements.

- The base seal is the simplest & easiest to install. You can use a regular splicing iron to perform heat welding.

- Split water-stops come with a similar feature to dumbbell waterstops. What sets them apart is the structure & features. They are also ideal for construction joints with little or no movement.

- The cap water-stops come with a cap that ensures a fluid-tight internal seal. They are ideal for expansion joints with expansion boards.

Advantages

- Provides excellent corrosion resistance

- PVC water stops are ideal for low-temperature applications.

- They are 3-4 times more durable than rubber waterstops.

- Cheaper than rubber waterstop

Limitations

- Not flexible as rubber waterstop

- Not suitable for use on irregular surfaces

4 Main Considerations to Consider While Choosing a Waterstop (Rubber Waterstop vs PVC Waterstop)

In the preceding sections, we have gone through a brief description of rubber waterstop & PVC waterstop. Now, you can distinguish their differences. Let’s recap our discussion & evaluate how to choose the right product for your project. To do this, we can simply consider four important Factors.

Factor#1 Material

The material of a waterstop is a critical determinant of its performance. You know, rubber & PVC each offer distinct properties. Consequently, these material properties affect the durability, flexibility, and resistivity. Therefore, the selection must align with the specific demands of the project. As a result, you or your engineer can ensure that the chosen waterstop can withstand certain environmental conditions.

Factor#2 Installation method

The installation method also significantly influences the functionality of the water. Two types of installation methods are often used in construction applications. These are internal & external installations. Moreover, proper installation ensures a secure & watertight seal. It prevents leaks & ensures long-term effectiveness. Well, the method may vary depending on the chosen waterstop material.

Factor#3 Size

Size considerations are also paramount in achieving an optimal seal. The waterstop you choose must be appropriately sized to accommodate concrete joint movement. It also prevents displacement. Oversized or undersized waterstops can compromise the overall effectiveness of the seal. Therefore, it is necessary to go for precise sizing.

Factor#4 Application Environment

Finally, when choosing the right type, evaluating the application environment parameters is necessary. Rubber waterstops may be excellent in certain conditions, while PVC waterstops might be more suitable in others.

FAQ

Q1. What are the different types of water stops?

Answer: There are four types of waterstops that you can use in your construction. These are rubber waterstops, PVC waterstops, metal waterstops & bentonite waterstops. Rubber waterstops & PVC waterstops are considered the most popular in this case.

Q2. Which is better rubber waterstop or PVC waterstop?

Answer: The choice between rubber & PVC waterstops depends on specific project requirements. For example, rubber waters are ideal for flexibility & adaptability in construction joints. Conversely, PVC waterstops are known for their corrosion resistance & low-temperature resistance.

Q3. How long does PVC rubber waterstop last?

Answer: Normally, plastic water stops’ lifespan is 3-5 times longer than typical rubber waterstops. Although, PVC rubber waterstops last more than 40 years. It typically depends on the right selection of the waterstops during the installation.

Q4. What is the difference between TPV & PVC waterstop?

Answer: TPV is a combination of rubber & plastic. It provides both characteristics of rubber & plastics. The main difference between TPV & PVC waterstop is their flexibility. TPV is more flexible than traditional PVC. Therefore, it allows for greater movement accommodation in construction joints.

Summary

Let’s wrap up everything! Rubber waterstops & PVC waterstops are both popular in construction applications. They reveal different characteristics that make them suitable for specific applications. Rubber waterstops offer enhanced flexibility & adaptability. On the other hand, PVC waterstops offer excellent low-temperature resistance & high corrosion resistance. Note that rubber waterstops & PVC waterstops may have some limitations. But it is obvious that one’s limitations are another’s benefits. Therefore, you must choose the right material for the project based on your application requirements.

As discussed in the preceding section, when choosing a waterstop material, you must focus on four factors. These are material, installation method, size, and application environment. The material choice, whether rubber or PVC, significantly influences the waterstop’s performance & longevity. Moreover, size considerations are also important for precision installation. Subsequently, the other two factors determine the longevity & functionality of the water stoppers.

Above all, if you have any questions on rubber waterstops vs PVC waterstops, feel free to contact our customer support team.