When it comes to rubber, silicone rubber is one of a kind. It is famous for being very strong even in harsh situations. Si rubber is a great choice for numerous industries because of its properties and ability to serve many purposes. It has become a staple choice in many areas, from medical advancement to automotive vehicles. Also, silicone rubber is often used to make seal strips.

Silicone elastomer has a lot of good qualities, but it also has some limitations. So, you should consider all these things when picking out the right material. That’s what this article is all about. We will learn about the distinct types of silicone rubber, their applications, and their properties.

What is Silicone Rubber?

You may often misunderstand the difference between silicon & silicone.

Silicon is a chemical element. Its symbol is Si comes with an atomic number of 14. Silicon is widely used in electronics and semiconductors. You may often find it in CPU motherboard chips, solar plates, and other electronic accessories.

Conversely, silicone is a synthetic polymer of silicone, oxygen, and hydrocarbons. It’s a flexible, rubber-like material. That’s what we are talking about in this section.

Silicone rubber is famous because it has the qualities of both silicon and rubber. It’s very resistant to heat, cold, and surrounding damage. Si rubber is a good choice for many uses because of this. You can find them a lot in consumer goods, automobiles, medical equipment, and construction.

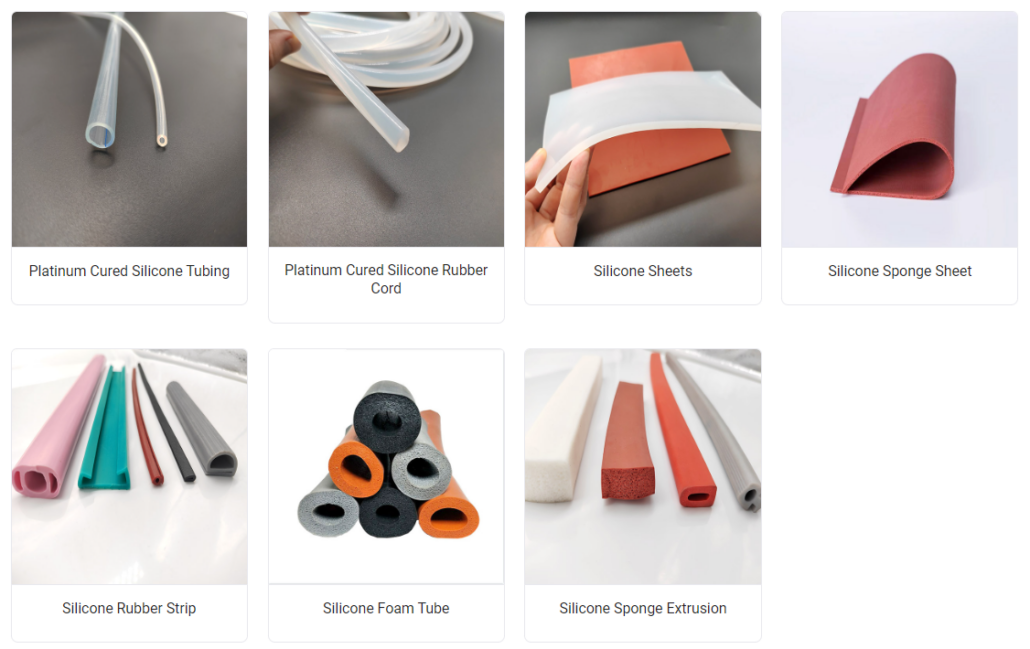

Si rubber comes in many forms and dimensions. You could make a gel, a resin, a liquid, or a rubber. You can prepare based on the application’s needs, no matter what it is. As a result, silicone rubber is also commonly used in other situations. Sealants, adhesives, lubricants, medical devices, cooking tools, and bakeware are a few examples.

How is Silicone Rubber Made?

Silicone is a flexible material that is used in many industrial settings. It goes through several steps in the making process. Here is a full description of the five steps used to make silicone.

Step #1 Silicon Isolation from Silica

Silicon is the main ingredient used to make rubber. The first step in the process is to get silicon out of silica.

Usually, several chemical reactions at high temperatures happen during this extraction process. People often call this process the reduction of silica. You already know that silica sand is made up of SiO2.

During the process, carbon is added to an electric arc furnace. It produces silicon and carbon monoxide gas. The process again refines it to achieve the desired purity level for silicone production.

Step #2 Combination of Silicon Powder with Methyl Chloride

After removing and cleaning the silicon, it is mixed with methyl chloride. You should know that the chemical formula for methyl chloride is CH3Cl. It is one of the crucial stages of making silicone rubber.

This mix usually takes place in a reaction vessel. Silicon and methyl chloride can react chemically better in a controlled setting. The product of this process is dimethyldichlorosilane, which is (CH3)2SiCl2. For silicone polymerization to happen, it needs to first be made.

Step #3 Mixture Distillation

The above mixture undergoes distillation in this stage. It typically separates and purifies the desired silicon compounds.

For this step, the mixture needs to be heated until it boils. It makes the parts evaporate, then the gas cools down and turns back into liquid. This process typically isolates specific silicon compounds from the reaction mixture.

Step #4 Water Addition

Water is added to the clean silicon molecules after distillation. Adding water is the first step in the hydrolysis process.

Hydrolysis creates hydrochloric acid (HCl) and di-silanol (Si-OH). The creation of di-silanol is necessary for the polymerization of silicone to happen later.

Step #5 Silicone Polymerization

Finally, the di-silanol goes through condensation reactions. In this stage, they form silicon-oxygen-silicon (Si-O-Si) bonds. It actually creates the formation of silicon polymers.

In addition, this polymerization process usually takes place in a controlled setting. In this case, having the right temperature, pressure, and catalyst helps with effective production. These factors ensure that the end silicone rubber has the desired qualities.

How do the Organic Groups classify Silicone Rubbers?

You can put silicone rubbers into different groups based on the organic groups.

We talked about the process of making Si rubber in the last part. And, we got a silicone elastomer with -CH3 groups connected to the silicon atoms. We used methyl chloride in the process.

So, we can say that silicone rubbers are grouped by the organic groups connected to the silicon atoms. In fact, these groups need to be linked together in their polymer chains.

These organic groups change the silicone rubber’s qualities and traits. Because of these special qualities, silicone elastomer is prevalent in distinct applications. Well, we can put silicone rubbers into three main groups based on their chemical makeup.

Type #1 Methyl Silicone Rubber

It is also known as polydimethylsiloxane. It contains methyl groups connected to silicon atoms. This type of rubber is prevalent for elastomers, silicone o-rings, silicone washers, silicone rolls, and medical tubing.

Type #2 Phenyl Silicone Rubber

It contains phenyl (-C6H5) groups connected to silicon atoms. They are better for withstanding heat, corrosion, and radiation. Therefore, you may often find it in automotive and electrical systems.

Type #3 Vinyl Silicone Rubber

It contains vinyl (-CH=CH2) groups connected to the silicon atoms. Vinyl’s cross-linking makes its mechanical qualities and tear strength better. As a result, it is often used to make molds, car parts, and industrial seals.

Types of Silicone Rubber Based on the Molecular Structure

Based on its molecular structure, we can divide silicone elastomer into three main groups. Each type has its own special features. They are all flexible enough to meet various customer and business needs.

Type #1 High Temperature Vulcanized (HTV)

Usually, HTV silicone rubber comes from a curing process at 150°Celcius. It is often called a high-temperature curing process. During this process, polymer chains connect to make a three-dimensional network. It keeps the material stable at high temperatures and makes it strong.

HTV silicone rubber is ideal for making seal strips and gaskets.

Type #2 Room-temperature vulcanized (RTV)

But RTV goes through a vulcanization process when it is at room temperature. It reduces the need for equipment that cures things with heat.

This kind of silicone rubber is well known for being used to make molds.

Type #3 Liquid Silicone Rubber (LSR)

There are two parts to liquid silicone rubber. Commonly, it has a base polymer and a curing agent. At room temperature, it reacts to make a flexible elastomer. Most of the time, LSR molding is used to make liquid silicone.

This silicone elastomer can be used in hospital settings, to care for babies, and in food-contact situations.

Advantages of Silicone Rubber

Silicone is made up of silicone, oxygen, and different organic groups. Each has its own beneficial features. But they all ensure safety at high temperatures, chemical resistance, and flexibility. Some types are also food grade. Therefore, they can be used in the food preparation, pharmaceutical, or medical fields.

Extreme Temperature resistance

You can use silicone rubber in a range of temperatures. Because of this, they are prevalent in places where temperatures vary often.

Chemical inertness

Silicone elastomer is also very resistant to chemicals. It works well with oils, acids, bases, and solvents. Because of this, they are excellent for use in chemical fields.

Excellent electrical insulation

Silicone elastomer also has high electrical resistance. As a result, they are ideal for use in electrical applications. For example, silicone o-rings and silicone elastomers used in electrical enclosures are noteworthy.

UV and ozone resistance

Silicone elastomer can also stand up to UV light and ozone. You know, UV radiation from sunlight is the main reason for rubber degradation. And because of this, silicone rubber can be used outside.

Flexibility and elasticity

In many different temperatures and pressures, silicone rubber stays flexible and stretchy. It lets the product keep its shape and ability to shut even after being compressed many times.

Biocompatibility

Silicone rubber is biocompatible. It means that it can work with living tissue safely. And you can safely use it in medical and healthcare applications. For example, medical implants, tubing, and medical devices are common.

Durable & Long lasting

All the above benefits tell you that silicone rubber is durable. It is excellent in resisting ageing, weathering, and degradation over time. It undoubtedly offers you reliable performance and extended service life in various applications.

Disadvantages of Silicone Rubber

There are many good things about silicone rubber, but it also has some problems. When compared to other rubbers, it costs more. Second, Silicone elastomer might not be good for uses that involve high pressure. Third, you might be unable to choose all the colors you want.

Because of these things, you should consider your application needs when picking rubber material.

Frequently Asked Questions

Q1. Are Silicone Rubbers Recyclable?

Yes, silicone rubber is recyclable. It allows you to reuse it. But recycling usually makes a product that isn’t as good as the original one. It is the only limitation of silicone rubber’s recyclability.

Q2. Is Silicone Rubber Toxic?

No, it is generally called non-toxic material. It does not release chemicals or toxins that are bad for humans. Because of this, silicone rubber is used in medical and food industries.

Q3. Is Silicone Rubber better than Natural Rubber?

Because of its benefits, silicone rubber is better than other materials. Conversely, natural rubber is cheaper.